We’re dealing with real artwork that will be printed for a real job. It’s for a left chest design they are printing that will not be needing an underbase. This artwork was given to me by a client of mine who is new to screen printing.

In this video, I will show a simple way to separate a design using some key tools in Illustrator. Luckily, the main roadblock people run into is but is over-thinking the process. This time they got our attention by introducing a thermochromic filament, which changes its color depending on the temperature.For some screen printers, using illustrator to separate colors can be overwhelming at times. Manufacturers often surprise us with something new and unusual, like adding sparkles or multicolored segments on the spool. (Image: Andrew Sink) Read More: Color Changing Thermochromic FilamentĪnother interesting desktop 3D printer material to try is the color-changing on temperature filament. The rainbow filament gives the model a gradual color transition.

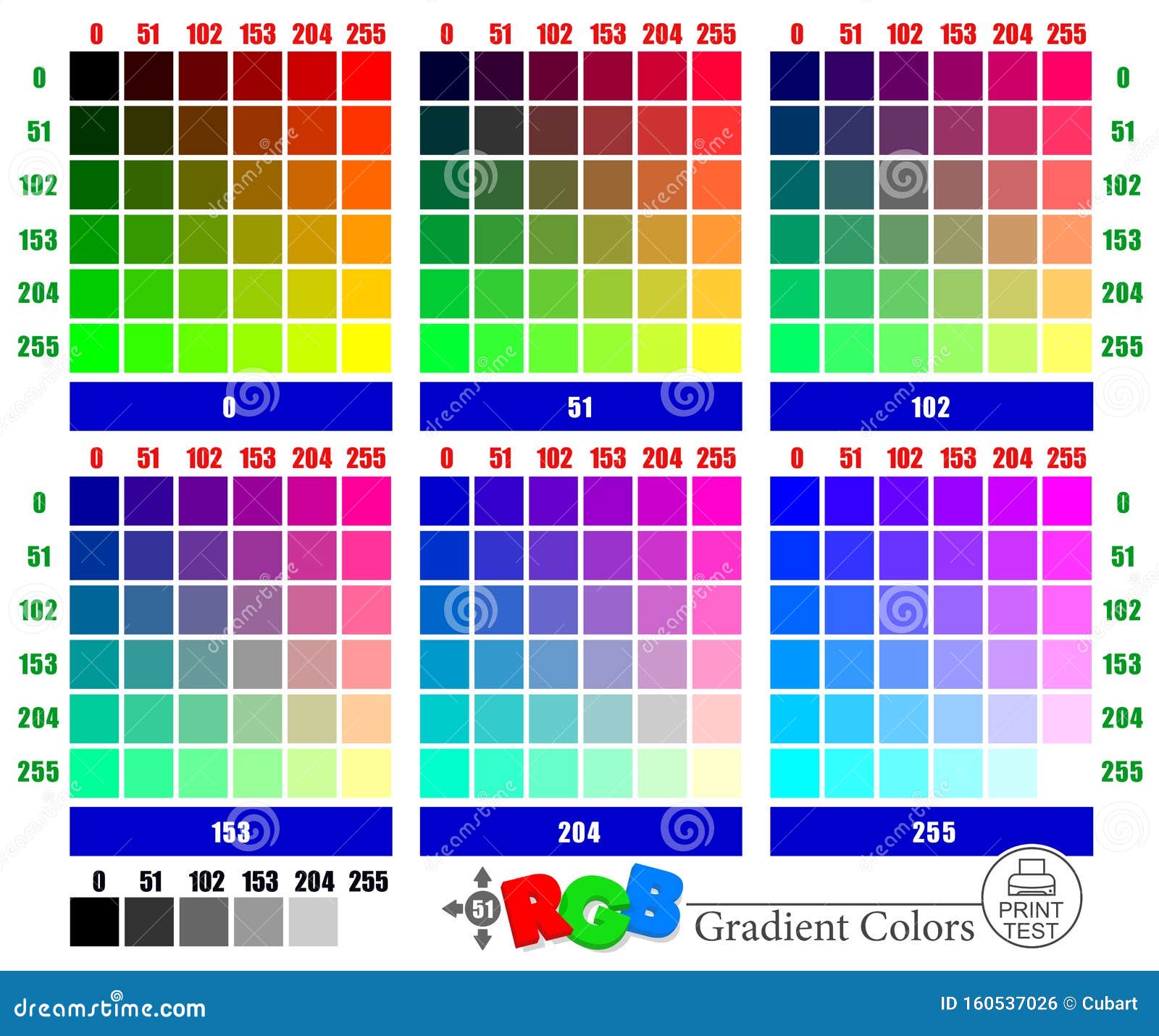

#ACCURIP GRADIENT TEST PRINT PRO#

I printed the Plunderbuss Pete model on Longer LK5 Pro 3D printer using the ‘Standard Quality’ print setting in Cura using TTYD3D rainbow PLA filament for this model. I was impressed with the overall quality of the material, and with a little bit of planning before a print (material usage, transition colors, etc.), I was able to make some very interesting-looking parts.

The Rock 3 Pro is the most recent large-format 3D printer released by Mingda, and works well when printing Silk PLA+ due to the BMG clone direct drive extruder and e3D clone hot end. To get a feel for what this transition looked like on a model with a higher level of detail, I printed out the Aquaticus Dragon by Makerbot on the Mingda Rock 3 Pro.

#ACCURIP GRADIENT TEST PRINT HOW TO#

(Photo: Andrew Sink) How to print in one color using Rainbow filament?

The denser print transitioned much more quickly and went through two complete color changes during the printing process.ĭue to the fact that the Silk PLA+ has an extremely reflective and shiny surface, I also noticed that “randomizing” the seams resulted in very visible defects at each layer where the toolpath would start and stop. The Yellow-to-Green cylinder was printed using a very light infill (1% Gyroid) and used a total of 36.59 grams of material, while the Yellow-to-Red cylinder printed with a more dense infill structure (20% Gyroid) and used a total of 114.92 grams of material. Rainbow Silk PLA – Transition Test Cylinders To test this theory, I set up an experiment to see how much influence over the transition speed I could have by altering the properties of the print. Prints that use more material will change color at a faster rate than prints that only use a small amount of material. Since the material changes colors throughout the spool, the speed at which the colors change is entirely dependent on how much material is used during the print.

SUNLU Rainbow Silk PLA Filament on Amazon (affiliate link) Experiments with Rainbow Filament Gyroid 1% and 20% Infill Structures Brands/Shops: SUNLU, Enotepad, Amolen, MIKA3D, CC3D, etc.

0 kommentar(er)

0 kommentar(er)